Double Threaded Insulators

By Robin Plewes

The feature of double threading has made many collectors wonder as to its purpose and origin. This threading feature is unique to two styles of Canadian insulators. Both the unembossed cd143 “tallboy” and the no name cd120 insulators are hard to find.

A quick definition of double threading is that there are two threads on the pin, which makes for a much steeper pitch. There are two thread starting points at the top of the pin hole, about 180 across from each other.

There have been a couple of theories as to what the purpose of the double threading may have been. We may never know for sure, as the manufacturer who made these insulators has not been confirmed with any certainty.

As the idea of threading insulators came into being, it is quite likely that it was simultaneously initiated by several glass manufacturers. Robert Hemingray, Louis Cauvent , Samuel Oakman and others worked at developing methods of threading that became the norm in insulator production. There is a very good chance that someone in Canada started up their own threading concept, independent of what was being developed in other glass houses. Cross country communications were no where near what we have today, so I can envision an innovative craftsman toiling away with existing insulator molds to come up with a threading concept to improve the threadless insulators, which had a bad habit of popping off the pins. We know that the double threaded insulators are some of the first threaded items to be manufactured. It has been shown that some of the double threaded 143s were in fact made in the threadless cd743.3 molds.

One idea as to the intent of the double threading is that it was an attempt to save some lineman’s labor in repairing the sometimes-troublesome threadless insulators. Perhaps the double threaded insulators were designed to thread onto threadless pins, thereby saving the lineman the trouble of changing out the pin as well as the insulator.

Threadless pins would usually be about 15/16” – 1” in diameter, based on the holes in most of the threadless insulators. The great example that I have personally seen was in fact whittled cedar and fit the insulator quite well. Some threadless were “glued” in place with tar and cloth. The threadless pin in this case would have to be a bit smaller in diameter to allow for the folded cloth and tar. Linemen of the time must have carried knives to trim the pins to suit the application at hand. Very few threadless pins have been found. Cedar wood would be easy enough to trim, but I’m sure there were other woods used also that would not be so easy to work with while up a telegraph pole. Likewise, linemen must have occasionally whittled pins on site from what ever was at hand.

A second possible purpose for the double threading is that it would allow the glass workers to make insulators a bit faster. The threaded plunger could be removed in about 3 rotations, which is about half the number of a standard threaded insulator. With 100s or 1000s of insulators to be made, manufacturing time must have been as important back then as it is today. With insulator machines already in use at this time by some manufacturers, this probably was not a big consideration. For those making insulators by hand though, it may have been a design factor.

There is another possible intent of the double threading that has also has a labor saving theme. The thread pitch or angle is quite sharp, so it only takes about 3 revolutions to travel the length of the pinhole. Maybe the concept behind the double threading was to save installation time of insulators and line construction overall. This would probably have worked had there been double threaded insulator pins to go with these double threaded insulators. Given that it is very tough to install a double threaded insulator on a standard pin, there would no time saved with this “improvement”. I know of 2 collectors who have personally removed double threaded cd143s in the wild. Given the difficulty of installation and removal on standard pins, I can’t see that these insulators would have been changed over the years. Therefore these must have been original installations. There has not been a double threaded pin reported to date, so the chances of one being found are very slim, given the scarcity of both double threaded styles.

Following this thought is the recent discovery of a tapered single threaded pin that allows for the speedy installation of a double threaded insulator and the jam fit of a threadless insulator. This pin may explain why there has not been a double threaded pin found {yet}. It would be easier to make a taped single threaded insulator pin than a double threaded pin. The tapered single thread design is a great idea for the transitional period between threadless and early threaded insulators.

Those collectors who have removed double threaded insulators from their original installations, may very well have overlooked the smaller diameter single threaded pins that were used. In one case though, the insulator was tough to remove, so it must have been jammed on a standard sized pin.

This tapered pin style probably saw even less use than the double threaded insulators. The example seen in the pictures is a side mount pin. If there was a machine making the side mount style, there was very likely a machine producing the straight-crossarm pins too. A newer standard threaded insulator does not thread onto this tapered pin {It just spins and doesn’t catch the threads.}, so the pin was no doubt made specifically for the double threaded insulators and/or threadless 742s that would have been in use at the same time.

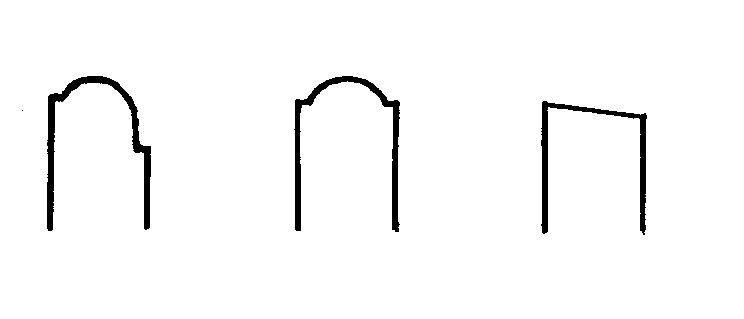

This picture shows 3 side mount insulator pins. The first on is a common one in great shape. The middle one is the slim tapered one that fits the double threaded and threadless insulators and the last one is also very old and it was found with a Mold-line-over-dome cd102 and still has one of it’s original square nail.

As with most small innovations, the product that gets accepted is the one that succeeds. The overwhelming numbers of early threaded Brookfield ( cd133s for example ) insulators found in eastern Canada suggest that there would be no way for a smaller Canadian glass house to compete with a different insulator threading style. It is very likely that the early equipment suppliers also provided insulator pins.

With the American suppliers able to provide large quantities of both pins and insulators, the Canadian innovation must have quickly fallen out of favor. To give an idea as to how quickly the double threading idea died, it is interesting to note that there are also standard threaded insulators (“Tallboys”) that were made in the same mold as the double threaded cd143s. This mold had previously been used for threadless 743.3 insulators also. The insulator mold was still fit for use, through 3 styles of threading. There are more standard threaded “tallboys” than double threaded versions around, leading us to figure that there was a relatively short run of double threaded insulators and a really short run of threadless insulators. This fits with the fact that the 743.3 insulator is very rare.

The cd120 insulator is also very scarce and it’s application is unknown. With the telegraph lines being the main destination for insulators in the 1880s, the cd120 style probably didn’t receive a lot of orders and may in fact just have seen a production run of a day or so. Early phone lines were being strung about this time, so the cd120 style was probably made to try and get a bit of this business.

This picture shows the most common color aqua on the left with a much less common light aqua on the right. There is a super rare dark cobalt blue also. It’s a real eye catching insulator with only about 3 known to exist at this time.

There are estimated to be no more than 2 dozen cd120s in collections today, so the insulator mold must have been set on the shelf shortly after it was proven. With an unpopular threading mandrel and a profile that was not in big demand, there would no reason to make more or retool the mold.

There is one other style of double threaded insulator that deserves mentioning. It’s a shorter, stocky style of 143 with a rounded base. The profile of this insulator is not quite as stocky as a Montreal Telegraph 143, but the rounded base in this case is unique to this one insulator. The rounded base that can be found on Hamilton Glass Co insulators, some unembossed Canadian styles and some Brookfield insulators is referred to as a mold line across base. This is where the mold line comes down the outer edge of the skirt and crosses the base to meet a mold line around the inner edge of the base.

The rounded base feature on the double threaded insulator can best be described as rounded continuous drip. There are a couple of styles of this rounded base as shown in the scale drawing below. The more common sloped flat base style is on the right hand side of the illustration. The left hand profile shows an offset rounded base where the inner shoulder is a ¼” lower than the outside shoulder.

The rounded base double threaded cd143 is a hard insulator to find. Perhaps the presence of this insulator means that there was more than one Canadian glass house experimenting with the double threading of glass insulators. There could also have been 2 or 3 separate molds at the one factory. If this was the case, then quite a bit of effort was put into the concept of double threading before it was dropped in favor of the single threaded design, that became the standard in insulator production.

There is a theory as to who may have made the double threaded insulators. The Hamilton Glass Company {1864 – 1891} was operating in the time frame of both threadless and threaded insulators. The little cd120 is perhaps the “link”, as it has the more common style of rounded base that is found on several other MLOD {Mold Line Over Dome} Canadian insulators, including the cd162 embossed Hamilton Glass Co.

The Hamilton Glass Co. was a very big plant in its time. They produced a wide range of products, which can be found in many areas other than southern Ont. Given that they produced in volume, they would presumably be willing to spend time and money developing improvements to their products. The concept of insulator threading would fit with this thought.

As with many early insulators, the color of these insulators was not an issue. What ever color of glass was in the furnace at the end of the shift or job, was made into insulators. For the eye-candy portion of this column, here are some of the rare standout colors that these insulators were made in.

A Few Special Double Threaded Insulators

The header insulator for this column is the taller version of the double threaded cd143 in aqua glass, the most commonly found example of double threading.

For this column I would like to thank Manfred Hagar, Phil Ort, Cecil Boos, Bill Meier, Dwayne Anthony and Ray Klingensmith for their valued contributions.

Good Collecting …….. Robin

Robin Plewes, McDonald’s Corners, Ontario.